How Can the Silt Screen Reduce the Wear of the Mesh Surface?

2025-09-01 07:45

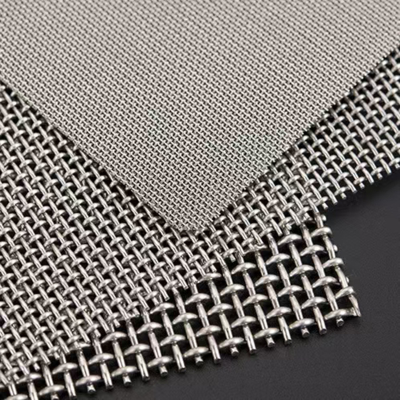

If the silt screen is to reduce the wear of the mesh surface, it is necessary to choose the right 316L stainless steel mesh, and ensure that the tension is appropriate and the mesh surface is kept flat during installation. It is necessary to regularly clean up residues and inspect equipment components. By doing this, the wear of the mesh surface can be reduced a lot.

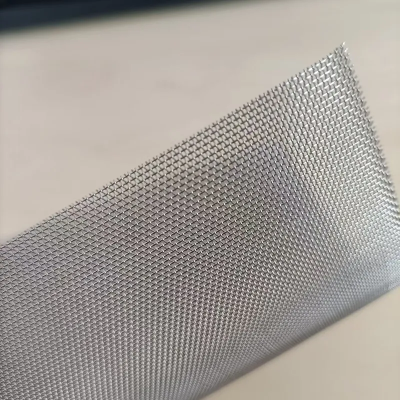

The 316L stainless steel mesh we produce is made of materials imported from Japan. The mesh structure design is very reasonable. It can stop impurities in the silt without letting hard particles get stuck in the mesh, reducing friction. The tensioning and flatness during installation are also very important. Our 316L stainless steel mesh has a certain toughness, and the appropriate size will be calculated according to the customer's screening equipment to keep the net in a stable state after installation. If the net is too loose, the silt will fall as soon as it is pressed, and it will easily rub against the frame; if it is too tight, the net wire will be subjected to too much force and may be worn off by hard particles.

316L stainless steel mesh has to be cleaned regularly, and our mesh surface is smooth, which is very convenient to clean up. If the organic matter in the silt is left on the mesh surface and dries, it will grind the mesh like sandpaper, but our 316L stainless steel mesh flushes with a high-pressure water gun, and the remaining silt will fall off. There is no need to scratch, which can reduce the damage to the mesh surface during cleaning.

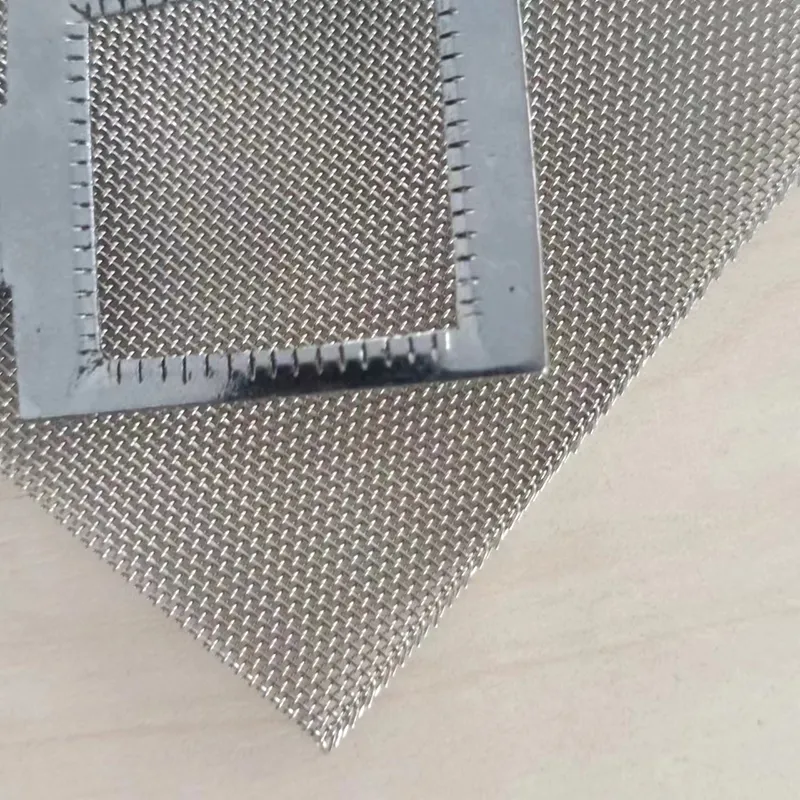

Our stainless steel SS 316 wire mesh has strong impact resistance, but we will still remind customers to check the equipment regularly. If the screen frame is deformed, we can customize a larger stainless steel SS 316 wire mesh according to the deformed size to make the mesh surface evenly stressed; if there is a problem with the vibration motor, we can also recommend that customers adjust the vibration frequency to reduce wear.

We also provide customized services. For example, if some customer equipment is round, we will make a round mesh with reinforcement strips on the edges to make stainless steel SS 316 wire mesh and the equipment more suitable; if the vibration amplitude of some equipment is large, we will thicken the edge of the mesh to increase wear resistance and ensure that it can meet the different needs of different customers.

The workshop of Shenyang Shuguang Network Industry Co., Ltd. has advanced processing equipment. Our technical team can quickly design a suitable network based on the equipment parameters provided by customers. The structure, size and thickness of the mesh can be adjusted. All stainless steel SS 316 wire mesh will be tested before leaving the factory to ensure that the products produced meet customer requirements, and we have also received the support and trust of many customers. In the future, we will continue to innovate to make the nets produced more suitable and durable. If you are interested in our stainless steel SS 316 wire mesh, please feel free to contact us!