Will the Stainless Steel Mesh Be Clogged When Screening Silt?

2025-09-01 16:41

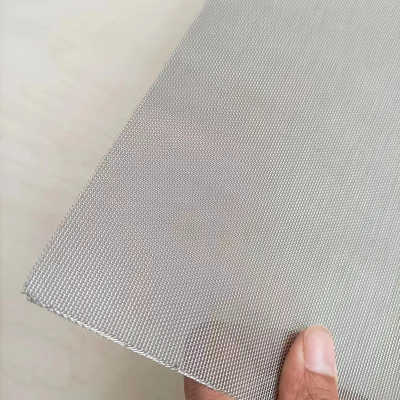

Will the 316 stainless steel mesh be clogged when screening the silt? If the viscosity of the silt is large, there are many impurities, and the mesh is too fine and the surface is rough, it is easy to be blocked by the silt, and blockage will occur for a long time; however, if the mesh surface is smooth, the mesh design is reasonable, and the material is durable, the blockage can be reduced.

The 316 stainless steel mesh we produce is made of 316L stainless steel wire imported from Japan, and clogging problems rarely occur when screening silt. The surface of 316 stainless steel mesh is very smooth, and the silt is not easy to attach to it. If there is a small amount of silt attached, it can be cleaned up by flushing with water. We have a customer in a sewage treatment plant who uses it to screen the silt of the river. There are many fine particles in the silt. The ordinary filter used before has to be cleaned several times a day. After replacing it with our 316 stainless steel mesh, it needs to be rinsed once in two days, which improves work efficiency.

Our 316 stainless steel mesh can withstand strong shocks in heavy-duty environments such as mining and metallurgy, and is not easy to break or deform. When screening silt, the equipment will vibrate, and 316 stainless steel mesh can maintain stable performance under vibration. The mesh will not become smaller due to deformation, reducing the clogging caused by silt stuck in the deformed mesh.

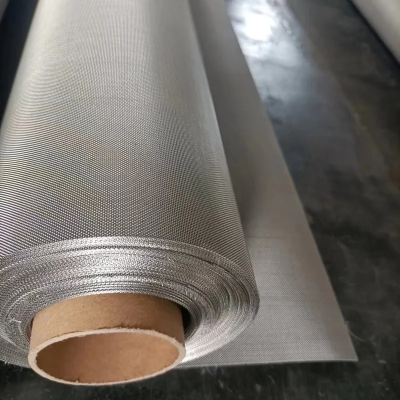

The mesh size of our stainless steel SS 316 wire mesh can meet the needs of screening. We will customize the appropriate mesh size according to the particle size of the silt. If there are many large particles in the silt, use a larger mesh to allow water flow and small particles to pass smoothly and reduce clogging; if the silt is relatively fine, use a finer mesh to stop impurities without being blocked because the mesh is too thin.

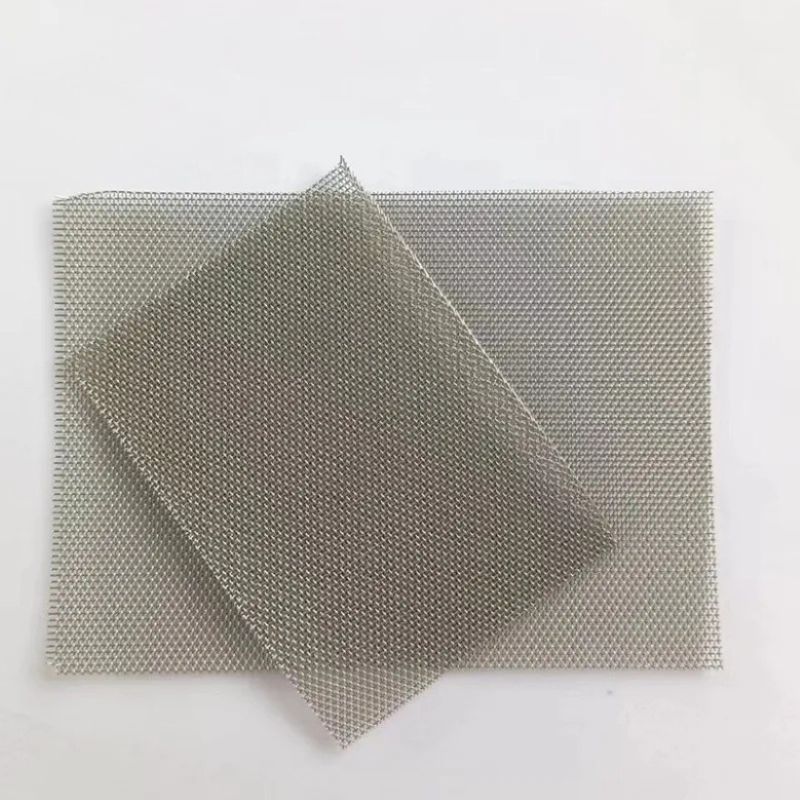

Our stainless steel SS 316 wire mesh can work stably for a long time in harsh environments. The silt will be corrosive, and the ordinary filter will be corroded quickly, and the mesh will easily rust and narrow. And our stainless steel SS 316 wire mesh has strong corrosion resistance and can be used smoothly in corrosive silt.

Different screening equipment requires stainless steel SS 316 wire mesh of different sizes and shapes. We can customize suitable products according to the equipment parameters provided by customers. In addition, our workshop has precision processing equipment, and the technical team is experienced, and can adjust the size of the mesh, the size and shape of the mesh according to the specific needs of customers. All customized nets will be tested to ensure that they are not easily clogged.

Shenyang Shuguang Network Industry Co., Ltd. focuses on the production of woven mesh. Many customers have used our products and given us good reviews. And we will continue to innovate, optimize customized services, and produce more suitable stainless steel SS 316 wire mesh. If you are interested in our stainless steel SS 316 wire mesh, please feel free to contact us!