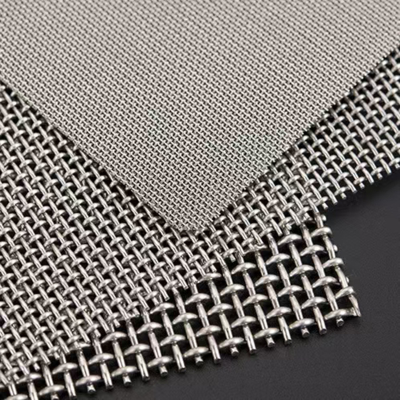

Stainless Steel Woven Mesh Solves Mining Screening Problems

2025-06-29 08:16

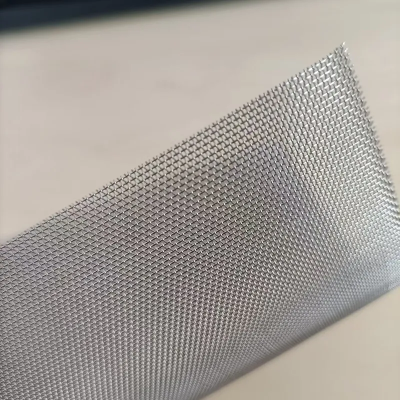

In high-wear screening such as coal mines and gold mines, traditional screens generally have problems such as short life and frequent replacement, which reduces production efficiency. Shuguang uses stainless steel woven mesh made of 316L high-grade stainless steel wire imported from Japan. The stainless steel wire mesh screen we produce is processed by special technology, with high strength and can adapt to more stringent working environments; we use imported raw materials, which can maintain excellent stability and durability even in harsh acid and alkali environments; in addition, we have precise control over the size of stainless steel wire mesh screen to meet high-precision requirements, and now it can be widely used in various industrial fields.

The actual application data of stainless steel wire mesh screen shows:

Coal screening: In sulfur-containing coal environment, the corrosion resistance life of stainless steel wire mesh screen is 4 times that of ordinary screens, and the screening efficiency is increased by 45%;

Gold ore sorting: stainless steel wire mesh screen with an aperture of 0.1-5mm achieves 99.2% particle size control accuracy and reduces precious metal loss;

Service life: The two-way wave-shaped locking process strengthens the edge structure, and the comprehensive service life exceeds 18 months.

At present, Stainless steel woven wire mesh has achieved 12 consecutive months of zero-failure operation in a certain group in Shanxi, and the screening efficiency of a certain gold mining industry has increased by 60%. We at Shuguang Networks will continue to provide cost-effective Stainless steel woven wire mesh products for the global mining industry through material technology and flexible intelligent manufacturing.

The deep customization capabilities of Shuguang Networks' factory truly cover all scenarios and provide customers with real solutions. The factory can produce ultra-fine Stainless steel woven wire mesh as fine as 0.5 microns, which perfectly meets high-precision applications such as precious metal recycling and improves resource utilization. The most surprising thing is our fast delivery link. We only need 48 hours to complete the customized production of Stainless steel woven wire mesh. At the same time, we also support more than 20 innovative processes such as reinforcement and strengthening to efficiently respond to emergency needs, saving users time and worry. This all-round service capability not only improves production efficiency, but also brings reliable customization guarantees to all walks of life.

Shuguang Networks not only strictly controls quality during the production process, but also pays more attention to the sustainable development of products. The 316L Stainless steel woven wire mesh developed by our company uses imported high-quality raw materials, meets international standards, and is widely used in the production of UHV transformer insulation boards. It has become a must-have product for well-known power companies at home and abroad. We have an experienced technical team ready to provide professional technical support to customers at any time. Whether it is the installation and use of stainless steel wire mesh screen or special application requirements, our technical experts can provide detailed answers and guidance. Customers can contact us by phone, email or online customer service, and we promise to respond within 24 hours to ensure that your problem is solved in a timely manner.