Does the Tilt Angle of the Screen Affect the Material Flow Speed?

2025-09-06 15:02

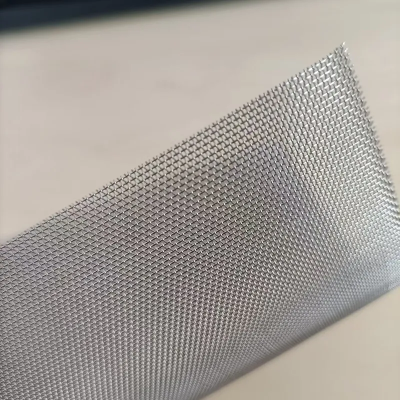

When 316L stainless steel wire mesh screens silt, the tilt angle will affect the flow speed of the material. If the angle is too small, the silt flows slowly on the mesh surface, easily accumulates together, and the screening is particularly slow; if the angle is too large, the silt flows too fast, and it slides over before it is completely sieved, and some impurities may be missed. Only by finding the right tilt angle can we screen evenly and improve work efficiency.

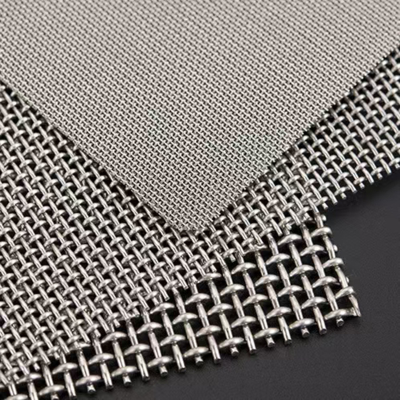

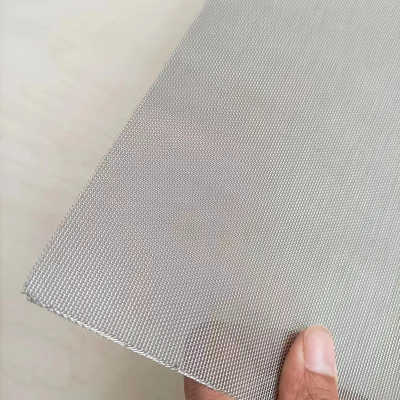

The 316L stainless steel wire mesh we provide is suitable for screening in various industries. Our wire diameters range from 0.02mm to 1.8mm, and the conventional mesh sizes are 20 mesh, 40 mesh, 100 mesh, etc. If these specifications do not meet the needs of screening silt, we can also customize the size according to the specific requirements of customers to help customers purchase suitable 316L stainless steel wire mesh.

Each batch of our 316L stainless steel wire mesh is produced in strict accordance with standards and is very corrosion-resistant. When screening silt, the mesh surface should often be soaked in water, and it will also come into contact with various impurities in the silt. Ordinary screens are very easy to corrode, and the mesh wire will break soon, which affects the stability of material flow. And our 316L stainless steel wire mesh has strong corrosion resistance, is not easy to rust in a humid silt environment, and the mesh surface can be kept flat. A customer of a sewage treatment plant used our 316L stainless steel wire mesh to screen silt. After more than half a year, the mesh surface is still well preserved, and the flow rate of silt has been very stable.

We have advanced testing equipment and strictly test every batch of nets produced to ensure that we can meet the requirements of customers around the world. The flatness of the mesh for screening silt is also very important. If the mesh surface is uneven, even if the angle is right, the silt will accumulate and the flow speed will become uneven. The stainless steel SS 316 wire mesh we produce, the mesh surface has been strictly tested to ensure that the silt can flow smoothly at different tilt angles, and there will be no local Caton.

We can provide customized services. Different equipment can adjust different tilt angles. We can customize the size of the net according to the angle range of the equipment to make the net more stable to install on the equipment. One customer's dredging equipment is very small, and the angle adjustment range is relatively special. We customized the adapted stainless steel SS 316 wire mesh. After installation, the silt can flow evenly along the mesh surface without accumulation problems.

Our production capacity can meet these customized needs, small batches of special specifications, or large quantities of conventional orders, we can produce efficiently. Our technical team will understand the angle parameters and silt characteristics of the customer's silting equipment, and recommend suitable wire diameters, meshes and fixing methods to ensure that they meet the customer's needs.

Shenyang Shuguang Network Industry Co., Ltd. the stainless steel SS 316 wire mesh quality is stable, and many customers who use our stainless steel SS 316 wire mesh have given us good reviews. We will also continue to do a good job of customized services to produce more suitable stainless steel SS 316 wire mesh. If you are interested in our stainless steel SS 316 wire mesh, please feel free to contact us!