How to Solve the Corrosion Problem of Woven Mesh During Filtration?

2025-08-02 14:22

Corrosion of stainless steel wire mesh screen often occurs in corrosive environments such as chemical industry and seawater desalination. Corrosion will not only reduce the service life of the stainless steel wire mesh screen, but may also contaminate the filter material and affect production quality. So, how to solve the corrosion problem of woven mesh during filtration? It is important to choose the right material. The right material can enhance the corrosion resistance of stainless steel wire mesh screen.

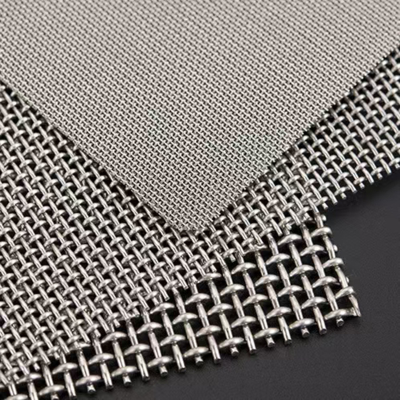

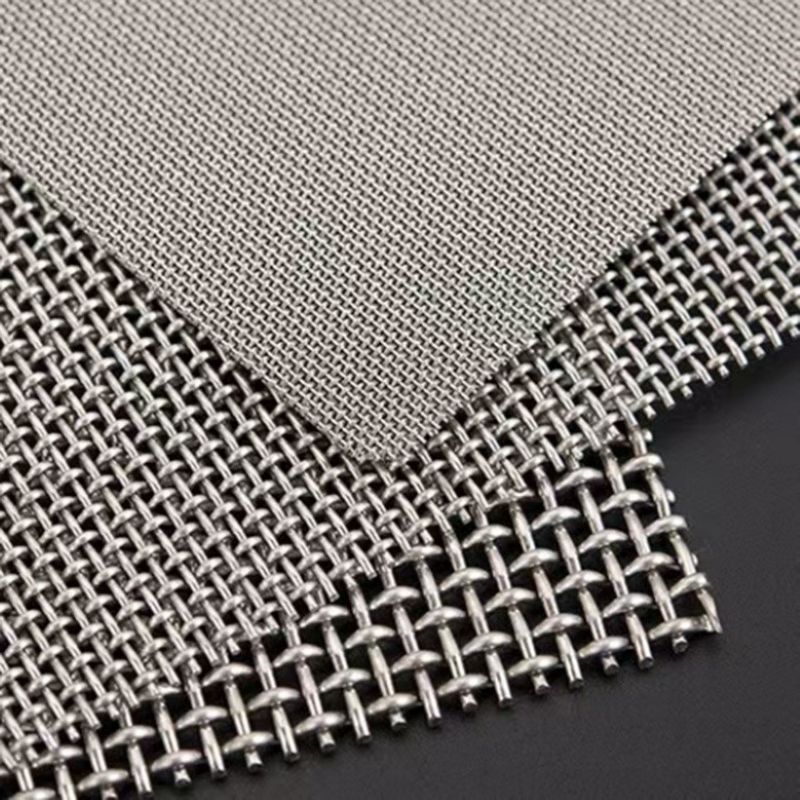

The stainless steel wire mesh screen we produce uses 316L stainless steel wire imported from Japan. This molybdenum-containing material has stronger corrosion resistance than ordinary stainless steel.316L stainless steel can effectively reduce corrosion, especially suitable for use in coastal power plants or aquaculture. For strong acid and alkali working conditions, we also provide treated stainless steel wire mesh screen, which has much better chemical resistance than conventional materials. All our raw materials have material reports to ensure that the ingredients meet the standards.

The surface treatment process is also very important. We polished the mesh stainless steel woven wire mesh screen to form a uniform protective film on the surface, which can be well separated from corrosive substances. In the weaving process, we optimized the design of the knot to make the overall mesh smoother and smoother.

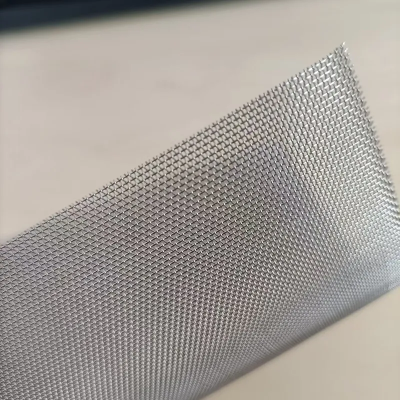

The correct use method can give good play to the corrosion resistance of the material. We recommend that customers choose the appropriate mesh size according to their own needs. Meshes that are too small are easy to accumulate corrosive substances and cause clogging. Ensure that the tension of the mesh surface is appropriate during installation. The mesh surface should be cleaned regularly with water or cleaning agent to remove corrosive residues. For equipment that has been out of service for a long time, it is recommended to disassemble the mesh stainless steel woven wire mesh screen and store it dry. Our technical team will provide use and maintenance guidelines according to the specific work conditions of customers.

The mesh stainless steel woven wire mesh screen we designed for food companies is surface treated, and the products provided for the pharmaceutical industry meet the standards through treatment. Our customized service allows every mesh stainless steel woven wire mesh screen to remain stable in a specific environment, and our factory has advanced equipment to produce products that meet large-scale engineering projects and meet the needs of small batch orders. All products are tested before leaving the factory, so that the products produced meet industry standards.

Shenyang Shuguang Network Industry Co., Ltd. The use of high-quality materials and professional services can meet the different needs of different customers. We will continue to invest in research and development to provide customers with suitable products. If you are interested in our mesh stainless steel woven wire mesh screen, please feel free to contact us!