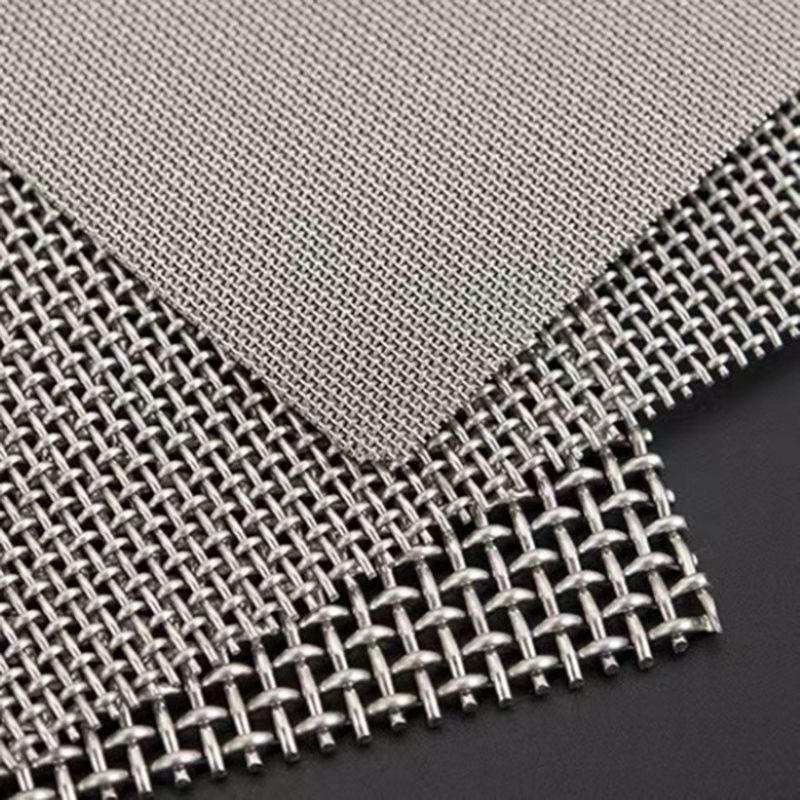

How Long Can the Stainless Steel Wire Mesh Screen Last?

2025-07-18 17:07

The service life of stainless steel wire mesh screenis of great concern to many industries. The length of its continuous use is not fixed and is affected by many factors. A good 304 or 316 stainless steel wire mesh screen can be used for 8-10 years in a normal environment. Customized products that have been specially treated may last longer. However, if it is in a humid, harsh environment with strong corrosive substances, or if maintenance is not paid attention to when using, the use time will be shortened.

The material can determine the use time. Ordinary 304 stainless steel mesh is suitable for most indoor environments and can be maintained in good condition under dry and non-corrosive gas conditions. In coastal areas or chemical sites, 316 stainless steel mesh is more suitable for those with higher nickel-molybdenum composition, and its salt spray resistance and chemical corrosion resistance are stronger.

The usage method also affects the usage time of the stainless steel wire mesh screen. For woven nets with long-term heavy pressure or frequent friction, it is recommended to choose products with thickened diameters. The special woven mesh we designed for mining machinery is woven with thick-diameter steel wire, and its service life is much higher than that of ordinary products. For filters that need to be disassembled and cleaned frequently, it is recommended to use a more flexible filament braided structure that will not be deformed due to repeated operations.

Shenyang Shuguang Network Industry Co., Ltd. For the production of stainless steel wire mesh screen, the raw materials are selected from high-quality stainless steel, such as 304, 316 and other materials. These materials themselves have good corrosion resistance. In the production process, the weaving process is also very critical. We use advanced weaving equipment to make the meshes tight and uniform. This structure can reduce the wear caused by uneven force and extend the service life of the product.

Moreover, our customization capabilities can be optimized for different usage scenarios. For example, in the food processing industry, customers need stainless steel wire mesh screen for filtration and drying. We will customize the mesh size and wire diameter thickness according to the characteristics of the food and the operating environment of the processing equipment. If you come into contact with a food processing environment with high humidity and acid-base residues, choose a material with stronger corrosion resistance, and then adjust the weaving density to make the mesh more wear-resistant and not easily scratched or corroded by food residues. There is also the chemical industry. In the face of highly corrosive liquid filtration, we will customize the stainless steel wire mesh screen with special coating treatment to enhance the corrosion resistance.

After-sales service is also guaranteed, and we provide exclusive maintenance recommendations to customers in different industries and different use scenarios. Through this kind of customized service for the whole process from production to after-sales, our stainless steel wire mesh screen strives to extend the use time and last longer for customers. If you are interested in our stainless steel wire mesh screen, please feel free to contact us!