Do You Know the Application Areas of Polyphenylene Sulfide PPS Filter Mesh Fabric?

2025-07-16 16:58

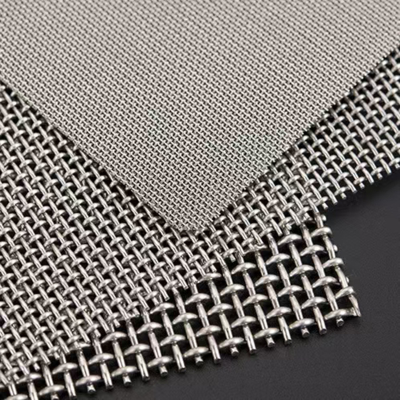

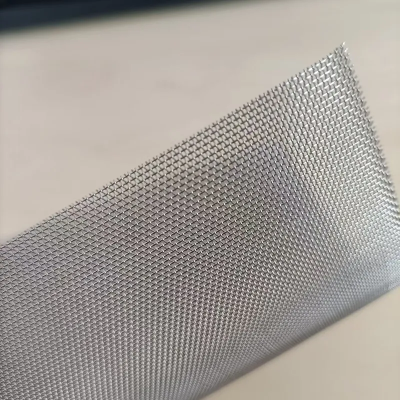

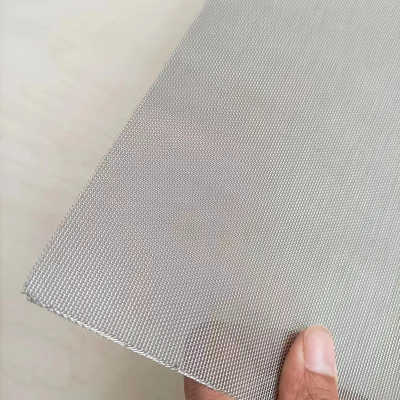

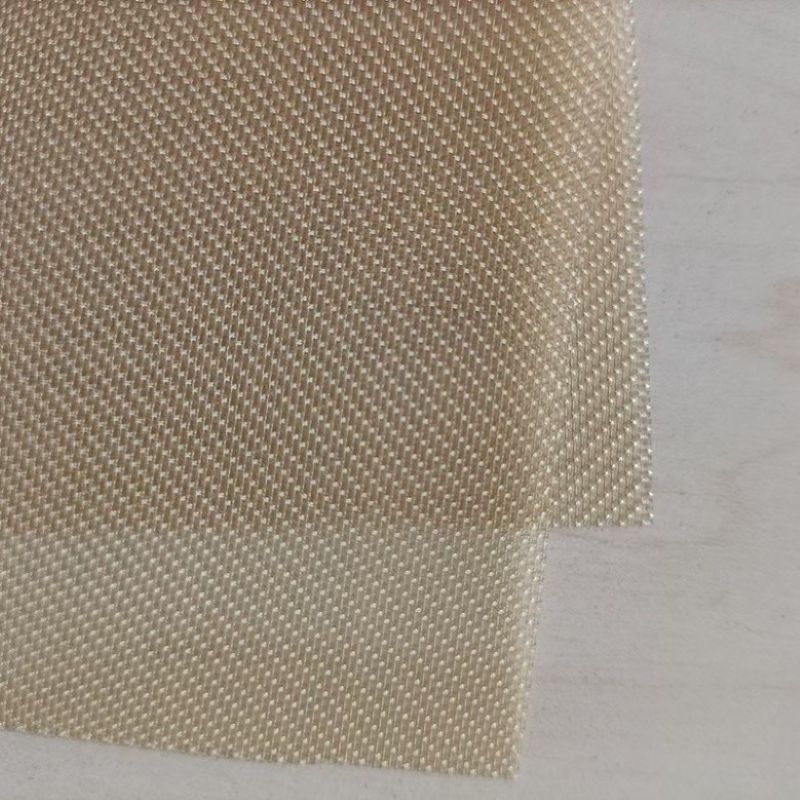

Polyphenylene sulfide PPS filter mesh fabric has the advantages of high temperature resistance and corrosion resistance. More and more industries use our PPS woven mesh. The mesh made of this material can be used in harsh environments. The polyphenylene sulfide PPS woven meshis also very light in weight and easy to process, and can be used in different scenarios.

Polyphenylene sulfide PPS filter mesh fabric can be used in the field of environmental protection. polyphenylene sulfide PPS woven mesh is a flue gas filter material that can withstand high temperatures and acid-base corrosion above 200℃. It is widely used in dust removal systems of power plants and waste incineration plants. Compared with traditional filter materials, the service life of PPS filters is more than 3 times that of ordinary filters, which reduces maintenance costs.

The automotive industry can also use polyphenylene sulfide PPS filter mesh . The battery diaphragm made of polyphenylene sulfide PPS filter mesh can provide safety protection for new energy vehicles. Such materials will not deform at high temperatures and can prevent short-circuiting of the battery. Some high-end models also use polyphenylene sulfide PPS woven mesh, which is a component of the intake system that can reduce weight and improve durability. And future cars will also be lighter, and our polyphenylene sulfide PPS woven mesh will be used more.

The electronic and electrical industry also uses polyphenylene sulfide PPS filter mesh fabric. Polyphenylene sulfide PPS filter mesh is used as the reinforcing layer of the circuit board, which will improve the product's more seismic resistance and dimensional stability. In the field of LED lighting, polyphenylene sulfide PPS filter mesh has good insulation and heat resistance, and is a good heat dissipation material. Some precision instruments use ultra-fine polyphenylene sulfide PPS filter mesh fabric as an electromagnetic shielding layer, which has a very good effect and does not affect the heat dissipation of the equipment.

Polyphenylene sulfide PPS woven mesh is also used in the new energy field. In the production process of lithium batteries, the filtration accuracy of the electrode material affects the performance of the battery. The uniform pores of the polyphenylene sulfide PPS filter mesh fabric can block very small impurities and improve the purity of the electrolyte. After many battery manufacturers used polyphenylene sulfide PPS woven mesh, the defective battery rate decreased by 25%, which increased production.

The polyphenylene sulfide PPS woven mesh we produce has a much higher strength than ordinary weaving methods, and has good breathability. Each batch of our products has undergone many tests such as temperature resistance and tensile strength to ensure that the performance meets the standard. And if there are special needs, we also provide customized services, which can adjust the mesh shape, fiber thickness and other parameters according to customer requirements to meet customer needs.

Shenyang Shuguang Network Industry Co., Ltd. focus on the production of woven nets. We use imported high-quality raw materials, which meet international standards, and our products are exported to Europe, America, Japan, South Korea and other markets, and are trusted by large chain companies in the global power field. If you are interested in our polyphenylene sulfide PPS woven mesh, please feel free to contact us.