Expanding The Plant to Increase The Production Capacity of Stainless Steel Mesh

2025-05-30 17:02

Recently, a customer asked us: Can you supply precision stainless steel wire mesh faster now? Can the specifications be more diverse? The answer is of course yes. Our factory is expanding the new plant and preparing to introduce a batch of more advanced and larger weaving machines and shaping machines. To put it more directly, it is "adding land, changing machines, and expanding production capacity", which is done in one step to fully upgrade our production capacity, product variety and delivery efficiency.

Shuguang The new plant has a larger area and a more reasonable layout, which can accommodate many different types of production lines. Whether it is high-precision woven mesh, welded mesh, or special-shaped customized mesh, it can be produced more efficiently. More importantly, the new equipment we are going to install has a higher degree of automation, which not only has a fast production speed, but also can achieve smaller errors and more stable quality. In the past, after the customer placed an order, we might need a few days to switch specifications or adjust parameters. Now with these new equipment, many specifications can be directly produced in parallel, and the efficiency has more than doubled.

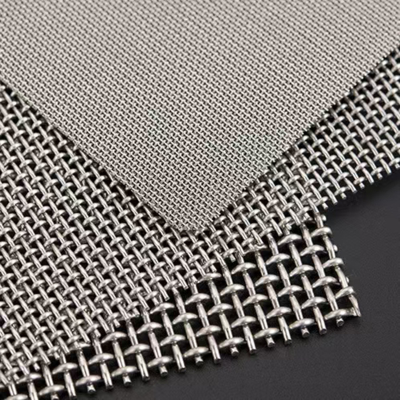

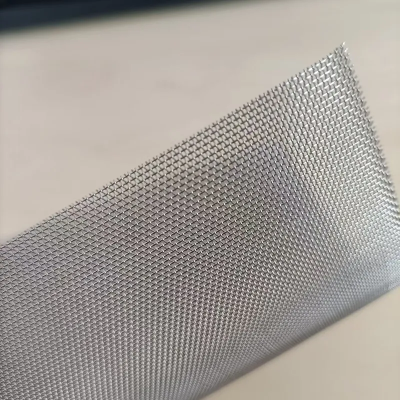

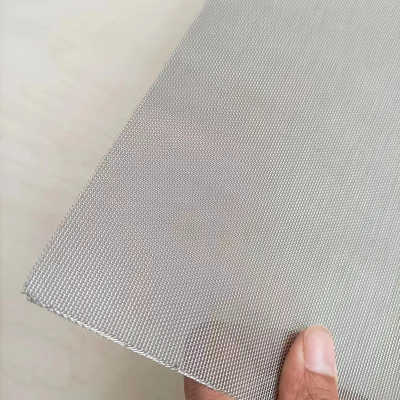

Some friends are curious, what types of precision stainless steel wire mesh are there in our house? In fact, it is very wide, including woven mesh, welded mesh, insect-proof mesh, filter mesh, screen mesh, punching mesh, etc. In terms of materials, 304, 316, and 316L are commonly used. Of course, we also support customers to specify special materials. Whether it is a high-clean filter used in food factories and pharmaceutical factories, or a high-strength protective precision stainless steel wire mesh used in construction projects, we can customize it on demand and ship it in batches.

Stainless steel wire mesh screen is not just as simple as weaving metal wires together. It has high requirements for mesh uniformity, wire diameter thickness, tension control, and shaping accuracy. Our team has more than ten years of experience in this area and has mature solutions for various complex weaving structures. The expansion of the new plant and the update of equipment have enabled us to make more special specifications that were previously limited and could not be mass-produced, such as ultra-fine wire and ultra-dense hole filtering stainless steel wire mesh screen, or large-size customized stainless steel wire mesh screen with a width of more than 2 meters.

In addition to equipment and production capacity, our services have also been upgraded simultaneously. After the customer places an order, we will have a dedicated engineer recommend the appropriate mesh, wire diameter and material according to the purpose to ensure that the product performance matches the use scenario. In terms of delivery, our newly built warehousing system can also arrange shipments faster and save waiting time.

If you are looking for an stainless steel wire mesh screen manufacturer, please feel free to call or visit us. Our new factory is always open for you to have a look. If you have any needs, come and talk. We may have prepared a production line for the product you need. We look forward to cooperating with you!