Will wet weather filtration accelerate the attachment of impurities?

2025-08-30 07:58

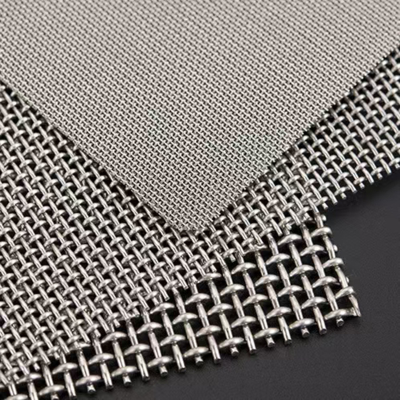

In wet weather, 316L stainless steel wire mesh may easily allow impurities to attach when filtering exhaust gas. Because in a humid environment, impurities such as dust and oil in the exhaust gas are easy to absorb moisture and become viscous, and they are easy to stick to the filter when they come into contact with it, and they may clump for a long time, which affects the filtration effect. But if the 316L stainless steel wire mesh itself has a smooth surface and good corrosion resistance, this situation can be reduced.

The 316L stainless steel wire mesh we produce, when filtering the exhaust gas in humid weather, impurities are not easy to attach. We use high-quality materials imported from Japan, the surface is particularly smooth, and those impurities with moisture are not easy to stick to it. We have a customer in the southern factory who often rains and uses our 316L stainless steel wire mesh to filter the exhaust gas of the workshop. The impurities on the mesh surface are only a thin layer. It is washed off with a high-pressure water gun. There is no clumping and clogging, and the filtration efficiency has been very stable.

Our 316L stainless steel wire mesh has particularly good impact resistance, even in mining and metallurgy industries, it can maintain a stable state and is not easy to break or deform. Even if the equipment vibrates slightly due to the influence of water vapor, 316L stainless steel wire mesh can maintain stable performance under high-frequency shock or severe vibration, and the mesh size will not be different due to deformation.

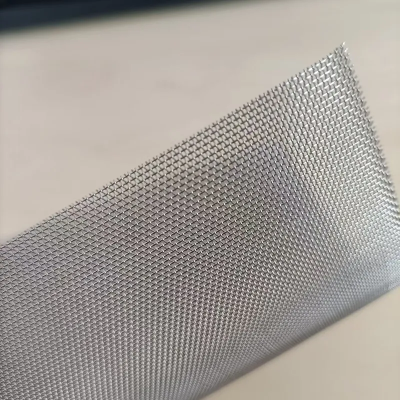

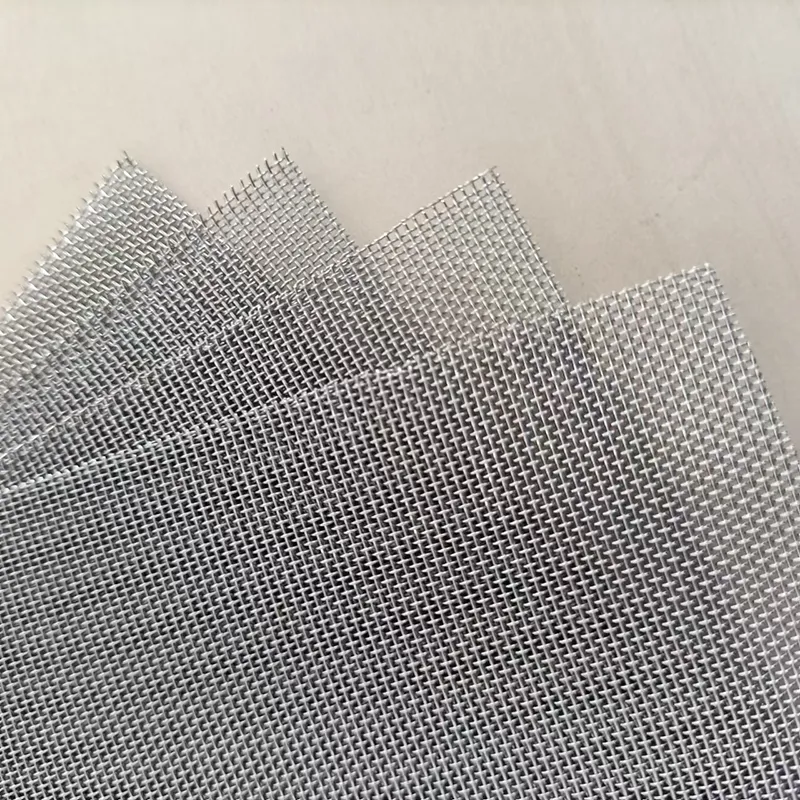

The stainless steel SS 316 wire mesh we produce can control the size of the mesh to meet the needs of customers in screening and filtration. In wet weather, uniform meshes allow air flow to pass smoothly and reduce the accumulation of impurities. For example, some customers need to filter exhaust gases containing fine dust. The size of our customized mesh is just right to intercept the dust, but it will not let the dust get stuck because of uneven meshes, which is more convenient to clean.

We can adjust the density and surface treatment methods of stainless steel SS 316 wire mesh according to the moisture level of the customer's area and the characteristics of impurities in the exhaust gas. If the customer's side is rainy all year round and there is a lot of oil pollution in the exhaust gas, we will make stainless steel SS 316 wire mesh smoother, and we can also increase the spacing of the mesh appropriately to reduce the adhesion of impurities; if the impurity particles that the customer needs to filter are more special, we can also customize the shape of the mesh according to the requirements.

Shenyang Shuguang Network Industry Co., Ltd. there are precision processing equipment in the workshop, and our technical team can adjust the production process according to the parameters provided by the customer, so that each batch of customized stainless steel SS 316 wire mesh meets the requirements. Many customers are very satisfied after using our stainless steel SS 316 wire mesh and have gained the trust of many customers. If you are interested in our stainless steel SS 316 wire mesh, please feel free to contact us!