Uses for Stainless Steel Woven Mesh in the Mining And Metals Industry

2025-06-22 09:27

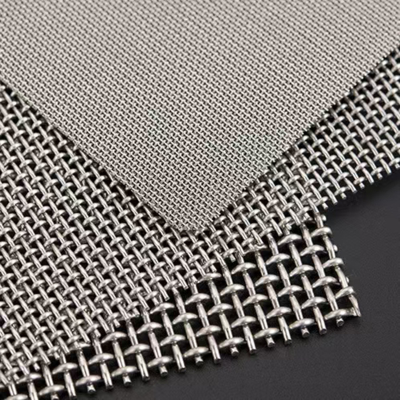

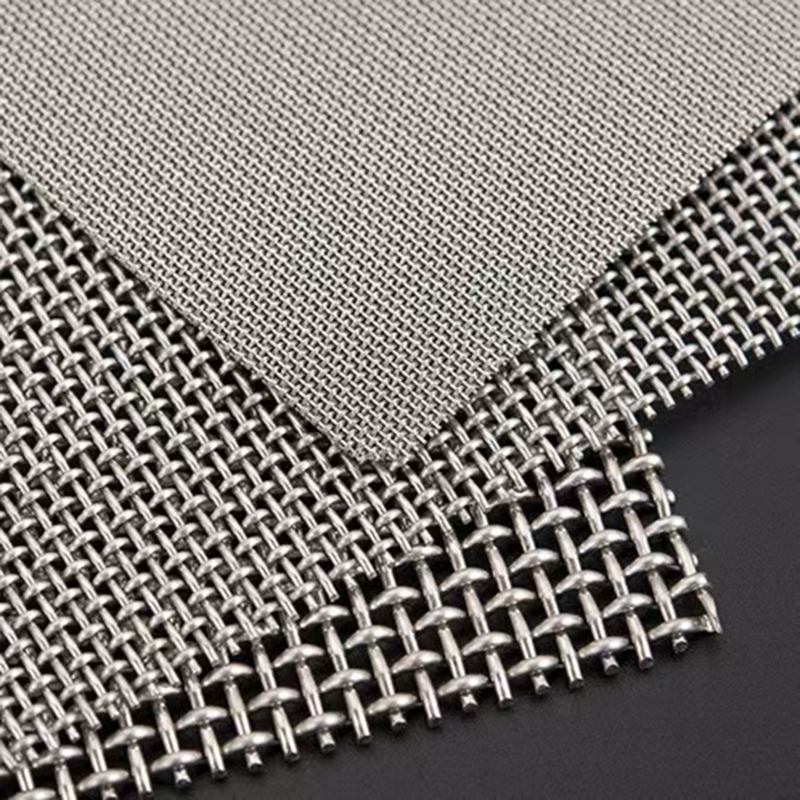

In the mining and metal processing industries, the wear resistance, corrosion resistance and high temperature resistance of stainless steel mesh are very high. Many customers gave feedback after on-site trials: I didn't expect such a delicate material to be so strong. Shuguang focuses on producing various types of Stainless steel woven mesh, and its products cover different wire diameters, apertures and weaving methods to meet the diverse needs of mining customers in screening, filtration, protection, transmission and other links.

Typical uses of stainless steel woven mesh in the mining industry:

Material screening and grading: Vibrating screens, drum screens and other equipment cannot do without the support of screens. Stainless steel woven mesh has stable aperture and strong impact resistance, which can effectively screen ores of different particle sizes, improve operating efficiency and reduce blockage.

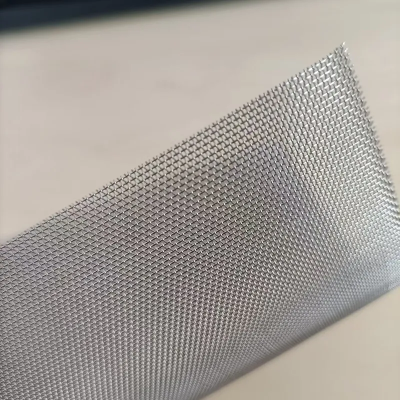

Filtration and dehydration treatment: In the treatment of tailings, slurry, and mineral processing water, Stainless steel woven mesh can be used to separate solid and liquid materials, improve filtration efficiency, and reduce water waste. We also provide high-density microporous mesh, which is suitable for fine filtration.

Safety protection structure: Stainless steel Woven wire mesh can be used as underground protection nets, equipment protection covers, fences, etc. It is both durable and does not affect ventilation and sight, ensuring a safer working environment.

Conveying system support layer: In the conveyor belt system of ore or coal, Stainless steel Woven wire mesh can be used as a load-bearing or supporting layer to enhance the stability of the conveyor belt and extend the life of the overall system.

High temperature resistant scene application: Stainless steel Woven wire mesh itself has good heat resistance and can be used for heat insulation, spark isolation and furnace protection in metallurgical high-temperature equipment, especially suitable for heat treatment and refining processes.

Our Stainless steel Woven wire mesh products are made of high-quality 304, 316, and 316L stainless steel materials imported from Japan, and are woven and formed by precision looms. Each batch of products must undergo strict tension testing, aperture measurement, and flatness inspection before leaving the factory. We know that for mining equipment, the accessories are stable, and the entire production line can be more assured. So our quality of Stainless steel Woven wire mesh has always been "I would rather check it three times and not miss a detail."

Some customers particularly like our customized service. Some people say, "Your technical team fits like a suit", because every time the customer explains the site conditions clearly, we can match the customer with the appropriate wire diameter, weaving method, and structural thickness, which is not only durable, but also reduces energy consumption and loss.

Many old customers repurchase every year. Stainless steel meshes are shipped from our factory to mining areas all over the country, and exported to project sites in South America and Southeast Asia. Although Stainless steel woven mesh is not the main equipment, its endurance and stability are precisely the important part of maintaining the smooth operation of the entire system.

If you are in the mining industry and have screening, filtration or equipment protection needs, you might as well consider our Stainless steel woven mesh. Come to our factory and experience it yourself, and you will understand why we have so many repurchase customers!