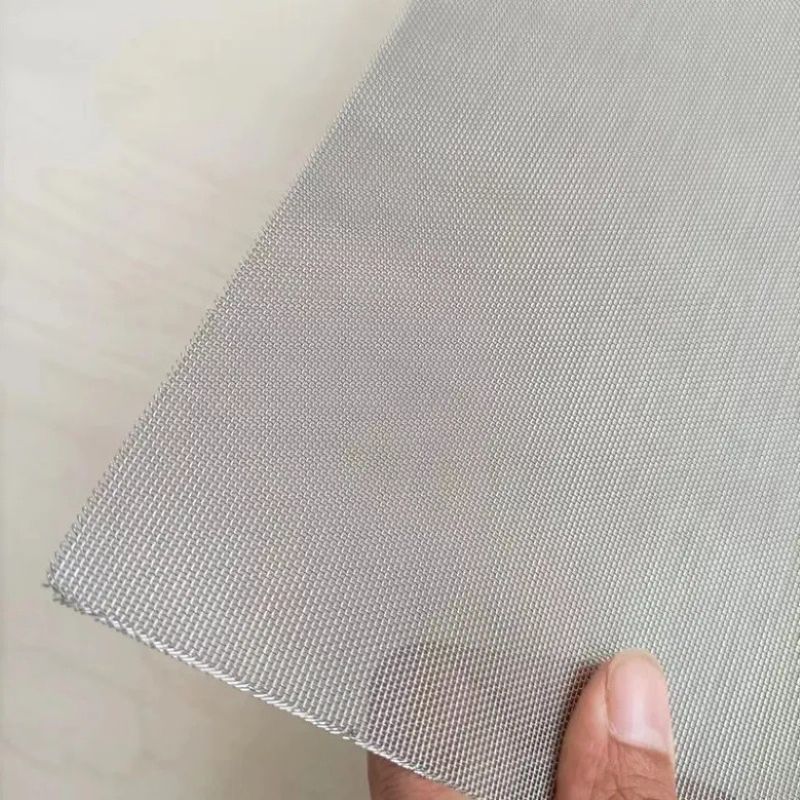

Does the Weaving Density Affect the Effect of Stainless Steel Mesh?

2025-08-01 09:17

The filtering effect of stainless steel wire mesh screen can affect production efficiency and product quality. Many users will have questions when purchasing screens: What kind of filtration differences will be caused by different weaving densities? The mesh density is related to the degree of filtration, circulation and service life. Choosing the appropriate weaving density can achieve a good filtration effect.

The high-density stainless steel wire mesh screen is suitable for filtering fine particles, such as powder screening in the food industry or filtration in the pharmaceutical industry. The high-density mesh surface can reduce fine impurities. However, if the density is too high, the resistance to circulation will increase, the processing speed will decrease, and the blockage may be increased. Although the low-density stainless steel wire mesh screen has a large flux, it may allow impurities to pass through the filter. Choosing the right density can improve the filtration effect.

We use 316L and high-quality 304 stainless steel wire imported from Japan, which can accurately control the weaving density according to customer needs. For viscous materials, we recommend choosing a loose woven structure with a special treatment process to ensure the accuracy of filtration and not easily stick to the mesh. Each of our stainless steel wire mesh screens has been simulated and tested to ensure a reasonable density distribution. And our technical team will understand the customer's material characteristics, flow requirements and working environment in detail, and recommend a suitable stainless steel wire mesh screen.

The tensile strength of our stainless steel wire meets industry standards, and even if the ultra-fine mesh is woven, it will not affect the stability of the structure. Enhanced mesh stainless steel woven wire mesh screen is used in the screening of mine gravel, which can maintain the screening effect of fine particles and resist the collision of large materials. We use advanced equipment to ensure that the size of each mesh is consistent. Our testing center has purchased laser measuring instruments to check the mesh size of all mesh stainless steel woven wire mesh screens to ensure that they meet customer requirements.

We also provide customized services, and we will provide special services according to the specific needs of our customers. For example, when some customers deal with liquid filtration, they need to stop impurities of a specific size, and at the same time ensure the filtration speed. We will select the appropriate weaving density according to the particle size and other parameters, and recommend the appropriate mesh stainless steel woven wire mesh screen.

Shenyang Shuguang Network Industry Co., Ltd. Through professional design, selection of high-quality materials and professional customization services, the filtration effect can be optimized, and it has been recognized by many customers, and we will develop better products to provide accurate mesh stainless steel woven wire mesh screen solutions for more industries. If you are interested in our mesh stainless steel woven wire mesh screen, please feel free to contact us!