How to Reduce the Wear of Stainless Steel Woven Mesh in Use?

2025-08-10 14:12

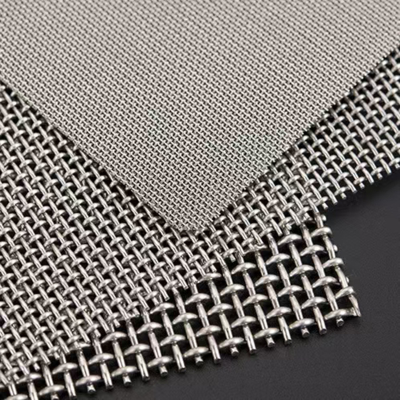

Stainless steel wire mesh screen is often used for screening in heavy industries such as mining and metallurgy. Many companies will think about how to extend the service life of stainless steel wire mesh screen, reduce frequent replacement, and reduce production costs? To solve this problem, material selection, design and daily maintenance are very important. The use of high-quality stainless steel wire and optimized weaving technology can improve the wear resistance of the mesh surface.

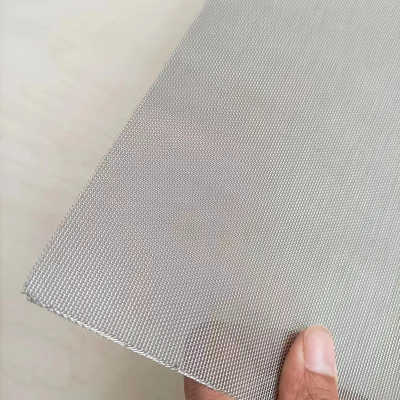

The most important thing in making stainless steel wire mesh screen is the choice of material. The stainless steel wire mesh screen we produce uses 316L stainless steel wire and high-quality 304 stainless steel wire imported from Japan. Both materials have good tensile strength and corrosion resistance.316L stainless steel is suitable for harsh environments with high salt content due to the addition of molybdenum, while 304 stainless steel wire is low in cost and wear-resistant. These high-quality materials can reduce the friction of the material, stabilize the shape of the mesh, and reduce local damage.

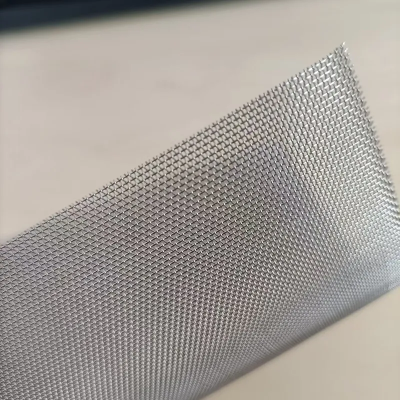

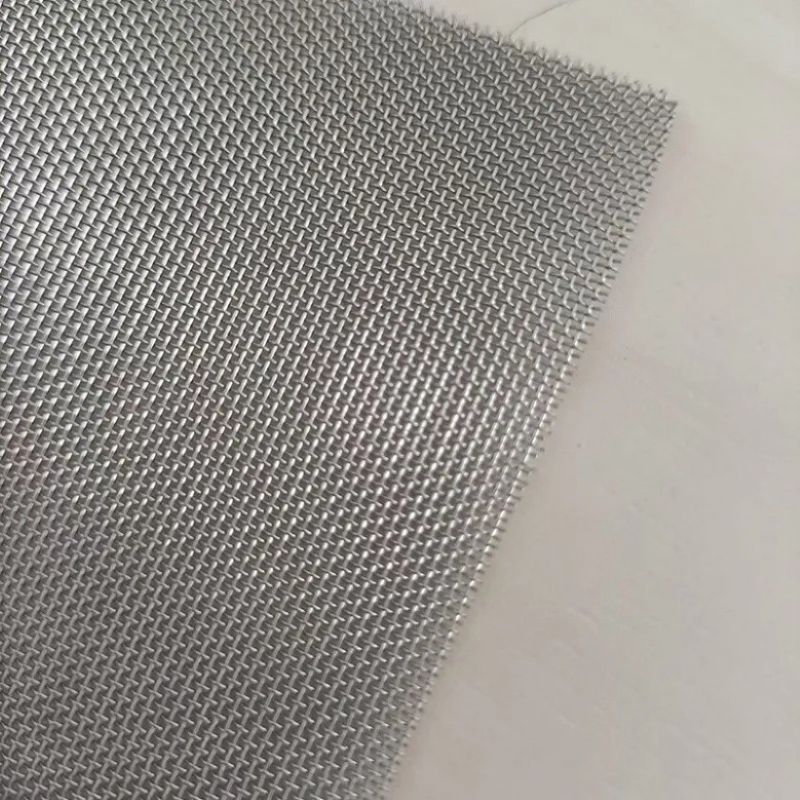

The weaving process also has an impact on the wear resistance of the mesh stainless steel woven wire mesh screen. We use special weaving techniques to make the connection between the meshes stronger. This structure can reduce the impact of the material. For the screening needs of different materials, we can adjust the size of the mesh and the thickness of the stainless steel wire. For edge parts that are easy to wear, we can also perform thickening treatment or special welding technology, which can extend the service life of mesh stainless steel woven wire mesh screen.

The correct installation and use of the mesh stainless steel woven wire mesh screen is very important. We recommend that customers check the woven mesh regularly. Too loose will cause the mesh surface to vibrate and increase the degree of wear. During downtime, the materials should be cleaned up in time to reduce the long-term attachment of corrosive substances. For different types of materials, our technical team will provide maintenance recommendations, such as adding pre-screening procedures for sharp ores.

We can not only provide standard products, but also customize solutions for customers. Due to the high hardness and coarse particles of the ore that needs to be sieved in the mining industry, the wear resistance and strength of the mesh screen are very high. We can adjust the thickness and weaving density of stainless steel wire according to the characteristics of the ore, and customize suitable products. The food processing industry pays more attention to the hygiene standards and mesh accuracy of mesh screens. We use corresponding processes and materials to customize woven meshes that meet food-grade standards and ensure wear resistance in use. All products have undergone rigorous testing before leaving the factory, so that the mesh stainless steel woven wire mesh screen performs stably and reliably in actual working conditions.

Shenyang Shuguang Network Industry Co., Ltd. there are complete production lines and advanced equipment, and quality control is carried out from the entry of raw materials into the factory to the packaging of finished products, so that the size of each mesh is consistent, which can meet the needs of large-volume orders and can also be customized in small batches. And we will continue to develop and produce products that meet customer requirements and provide customers with professional services. If you are interested in our mesh stainless steel woven wire mesh screen, please feel free to contact us.